How is waterproof performance achieved in WPC Foam Boards?

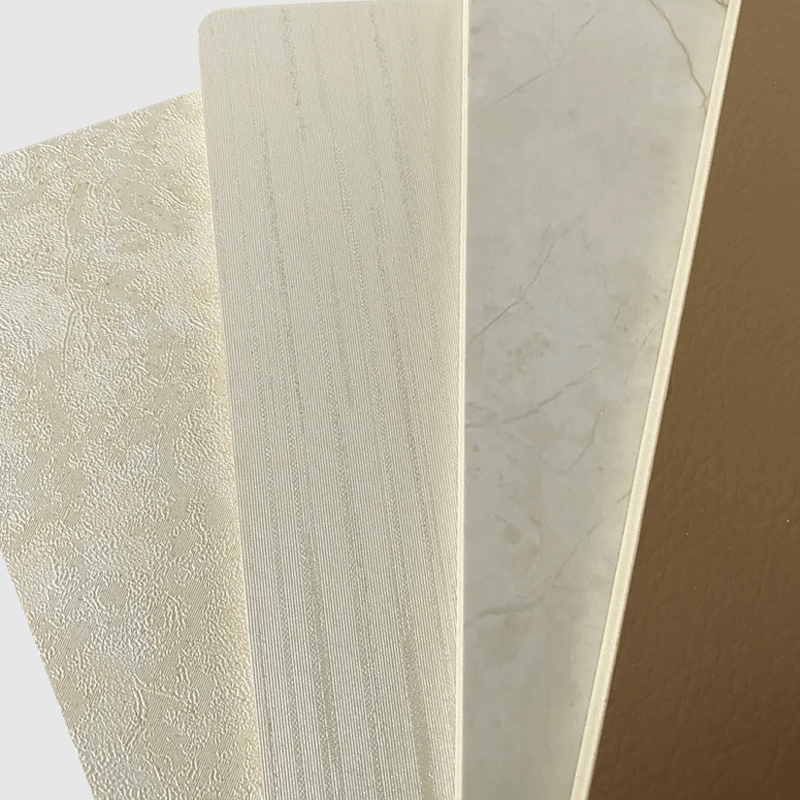

WPC is a new environmentally friendly building material that combines the advantages of wood and plastic. It not only has the natural texture and beautiful appearance of wood, but also has the waterproof, anti-corrosion, weather resistance and other properties of plastic.

1. Material selection and proportioning

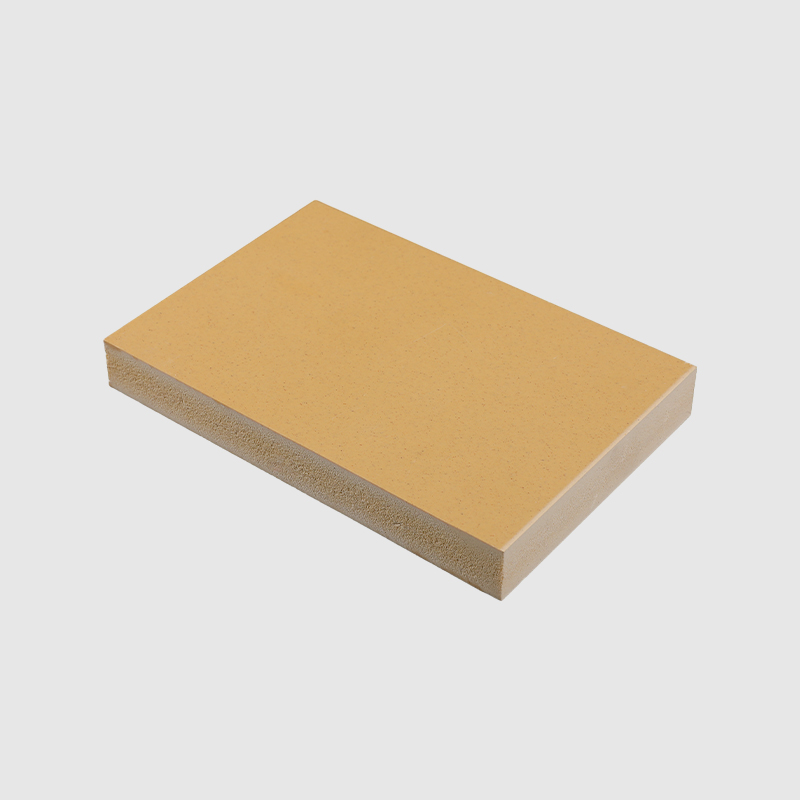

The waterproof performance of WPC foam board first comes from its unique material ratio. In the manufacturing process, high molecular polymers are used as the base material, such as polyethylene (PE), polypropylene (PP), etc. These materials themselves have excellent waterproof properties. At the same time, in order to enhance the strength and stability of the board, wood fiber, wood powder and other wood fillers will be added. These wood fillers are specially treated to bond tightly with the plastic substrate to form a uniform composite.

2. Production process

Mixing of raw materials: Mix the plastic base material, wood filler, additives, etc. evenly in a certain proportion to ensure that the various materials can be fully integrated.

Heated extrusion: The mixed raw materials are fed into the extruder and heated to high temperature to reach a molten state. During the extrusion process, the molten composite material is extruded into a sheet with a certain shape and thickness through the shaping effect of the mold.

Cooling and shaping: The extruded sheet is rapidly cooled in the cooling zone to fix its shape. At this time, the internal structure of the board gradually stabilizes, forming a dense waterproof layer.

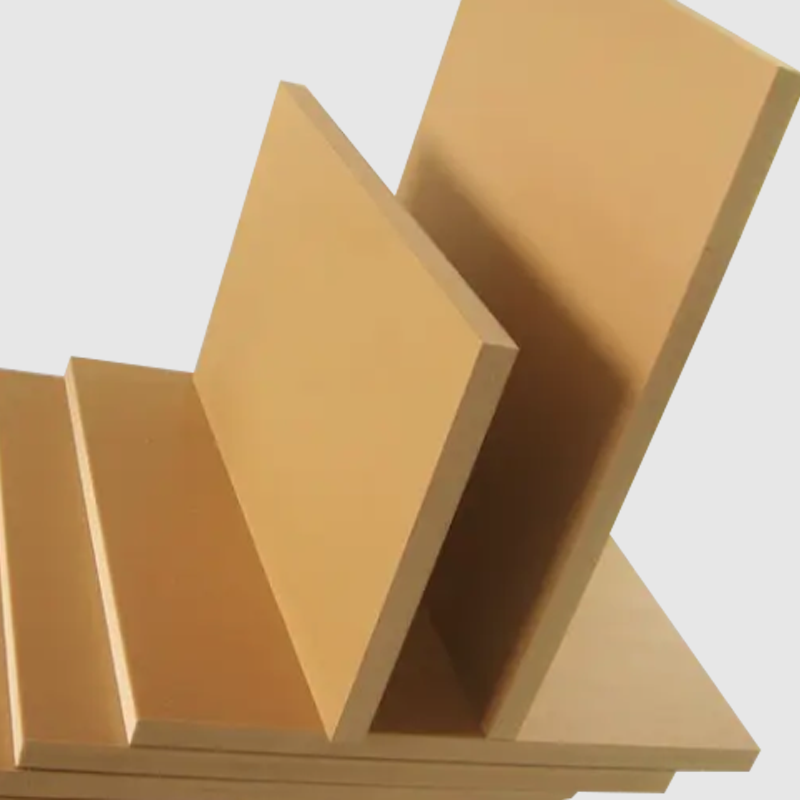

Surface treatment: In order to improve the waterproof performance of the board, the surface of the board will also be specially treated. For example, a layer of waterproof coating is applied to the surface of the board to form a dense waterproof film; or processes such as sanding and grinding are used to make the surface of the board smoother and flatter, reducing the possibility of moisture penetration.

3. Structural design

The structural design of WPC foam board is also an important part of achieving waterproof performance. WPC foam boards are usually designed with a multi-layer structure, with each layer having its specific function and purpose. This design not only enhances the overall performance of the board, but also pays special attention to the realization of waterproof performance. Generally speaking, WPC foam board contains at least three layers: Outer layer: This is the part of the board that is in direct contact with the external environment, so it must have excellent Waterproof properties. The outer layer is usually made of high molecular polymer materials. These materials have excellent water resistance and anti-penetration properties, which can effectively prevent moisture from penetrating into the interior of the board. Middle layer: This layer is mainly composed of foam materials, which provides the board with good thermal insulation properties. At the same time, due to the structural characteristics of the foam material, it can further prevent the penetration of moisture and enhance the waterproof performance of the board. Inner layer: As the support layer of the board, the inner layer also needs to be waterproof. This layer is usually made from a similar material to the outer layer to ensure the overall waterproofing of the entire panel.

4. Post-processing

In the production process of WPC foam board, post-processing is also a link that cannot be ignored. Through cutting, drilling, splicing and other processes, the plates can be processed into finished products of various specifications and shapes. During these processes, special attention needs to be paid to protecting the waterproof layer of the board to avoid damage to the waterproof layer during processing. At the same time, during the use and installation of the boards, corresponding measures also need to be taken, such as setting up waterproof gutters, using waterproof glue, etc., to ensure that the waterproof properties of the boards are fully utilized.

5. Quality control

In order to ensure the waterproof performance of WPC foam boards, strict quality control is also required. Choose raw materials that meet relevant standards and requirements, such as polymers, wood fibers, additives, etc. Conduct strict testing of raw materials, including physical properties, chemical properties, environmental indicators, etc., to ensure that the quality of raw materials is stable and reliable. Develop and strictly abide by the production process to ensure that every production link meets quality requirements. Strictly control parameters such as temperature, pressure, and time during the production process to ensure stable product quality. Use advanced production equipment and technology to improve production efficiency and product quality. Establish a complete product testing system to conduct comprehensive inspection and testing of the WPC foam boards produced. The testing content includes appearance quality, dimensional stability, physical properties (such as compressive strength, flexural strength, etc.), chemical properties (such as water resistance, corrosion resistance, etc.), safety performance (such as combustion grade), etc. Ensure that the test results comply with relevant standards and customer requirements, and rework or scrap products that do not meet the requirements.

The waterproof performance of WPC foam board is achieved through multiple links including material selection and ratio, production process, structural design, post-processing and quality control. These links are interrelated and influence each other, and together constitute the realization system of waterproof performance of WPC foam board.

English

English Español

Español عربى

عربى