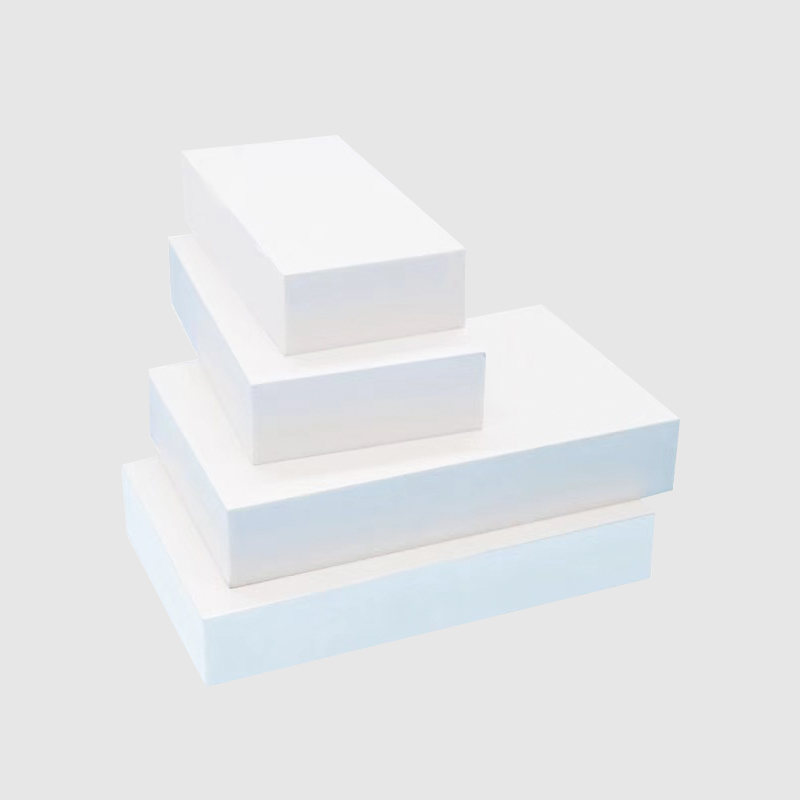

PVC Foam Sheets (PVC foam board), also known as Celuka Foam Board, is a lightweight, high-strength new environmentally friendly material made of polyvinyl chloride (PVC) and foaming technology. It has excellent waterproof, moisture-proof, corrosion-resistant, easy to process and other characteristics. It is widely used in advertising, construction, decoration, transportation and other fields.

Main features and advantages

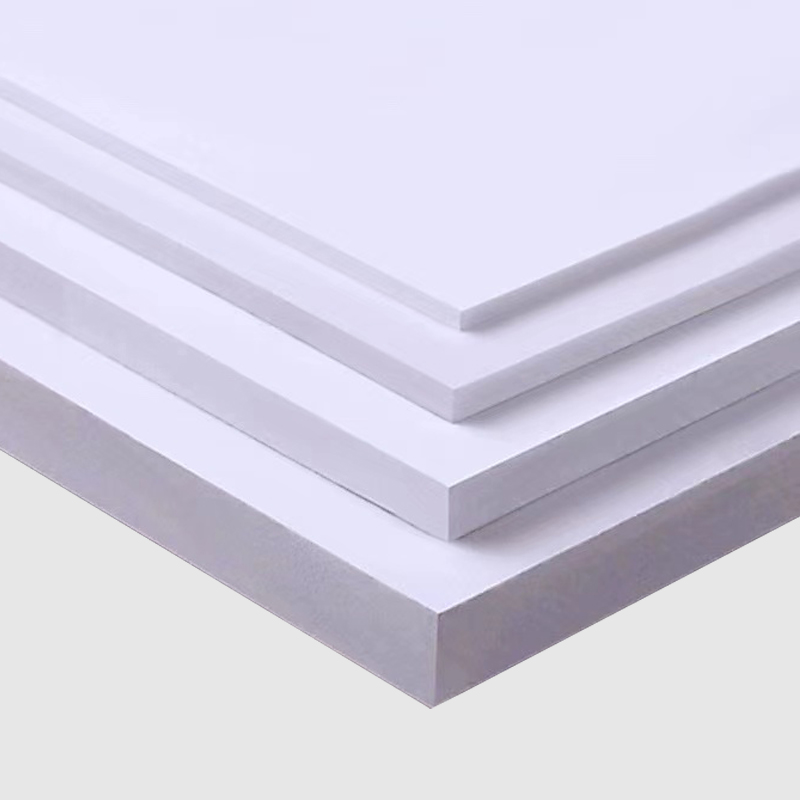

Lightweight and high strength: low density but strong impact resistance, easy to carry and install.

Waterproof and moisture-proof: non-absorbent, suitable for humid environments.

Corrosion-resistant: acid and alkali resistant, mildew-resistant, long service life.

Environmentally friendly and non-toxic: RoHS compliant and recyclable.

Easy to process: can be sawed, drilled, nailed, glued, hot-bent, compatible with a variety of processes.

Technical parameters (example)

Density: 0.45-0.8 g/cm³

Thickness: 1mm-30mm (customizable)

Size: 1220mm×2440mm (standard)

Surface: glossy/matte/wood grain/laminated optional

Fire rating: B1 (flame retardant optional)

Application areas

Advertising industry: display boards, signboards, UV printing substrates

Building decoration: partitions, ceilings, wall panels, bathroom cabinets

Transportation: ship interiors, passenger car/subway car panels

Industrial use: anti-corrosion lining, machine protection cover

FAQ

Q1: What are the advantages of PVC foam board compared with traditional wood board?

A1: PVC foam board is lighter, waterproof and moisture-proof, does not require anti-corrosion treatment, is formaldehyde-free, suitable for humid environments, has a longer service life than wood boards, and has low maintenance costs.

Q2: Can PVC Celuka board be used for outdoor advertising?

A2: Yes! It is weather-resistant and UV-resistant (some models contain UV coating), suitable for outdoor signs and display stands, and will not deform or crack after long-term use.

Q3: How to cut and process PVC foam board?

A3: It can be processed with woodworking tools (such as saws and planers) or CNC engraving machines. Hot bending needs to be heated to about 120°C. It is recommended to use PVC special glue for bonding, and the joints are firm.

English

English Español

Español عربى

عربى