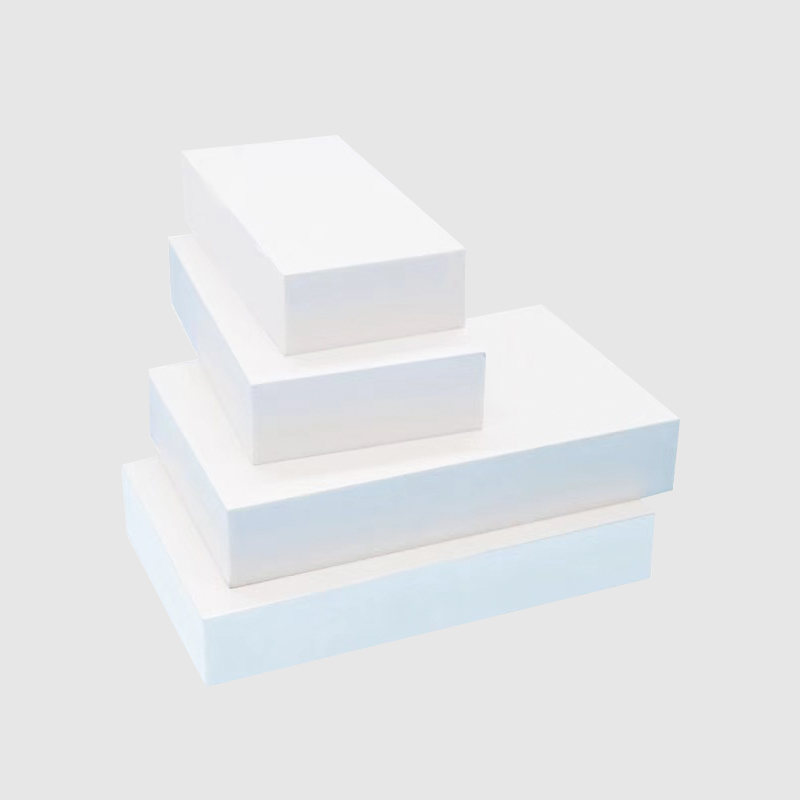

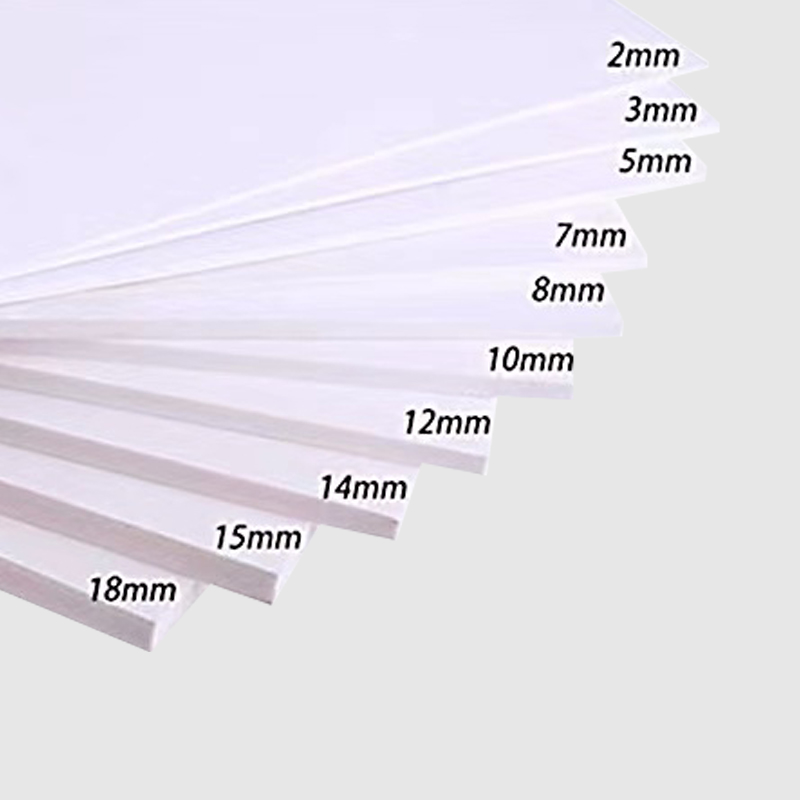

3mm 4mm 5mm 6mm White PVC Foam Board 9mm PVC Plastic Sheet 10mm Rigid/Celuka PVC Foam Sheet - Versatile Lightweight Substrate

Product Features

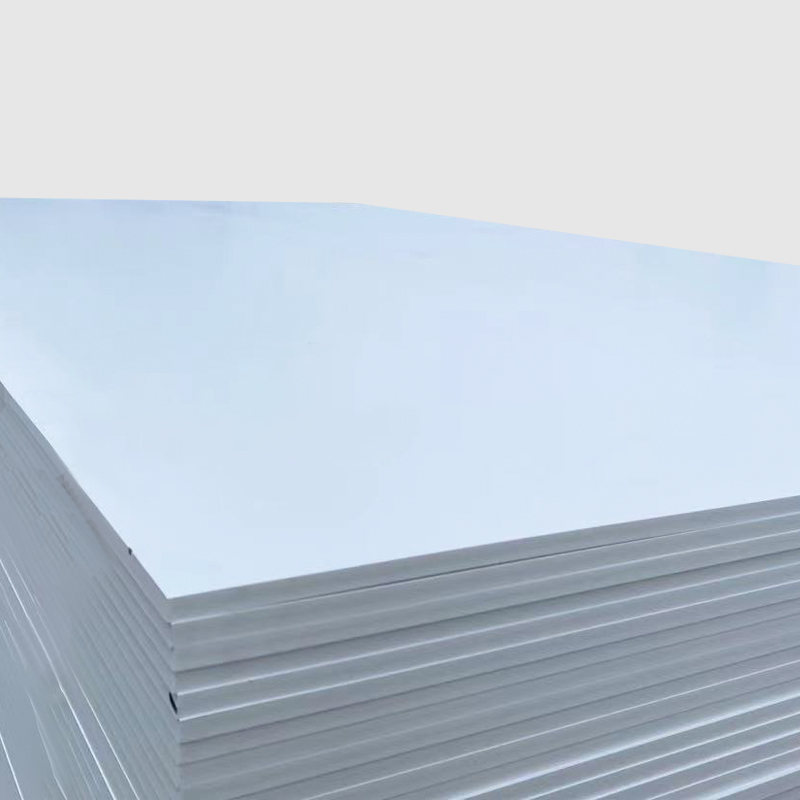

- Consistent Density and Uniform Surface: Our **white PVC foam board** is manufactured with a uniform cellular structure, ensuring consistent density across the sheet. The surface is smooth and matte, suitable for direct printing, lamination, and painting.

- Lightweight and High Rigidity: Despite its low density, this **rigid PVC foam sheet** offers excellent structural rigidity and dimensional stability, making it easy to handle and transport while maintaining its shape under various conditions.

- Exceptional Durability and Chemical Resistance: The **celuka PVC foam sheet** exhibits high resistance to moisture, chemicals, and impact. This durability makes it a robust material for both indoor and outdoor applications, providing a long service life.

- Ease of Fabrication: The material can be easily cut, routed, drilled, and heat-formed using standard tools. This feature is crucial for signage and display manufacturers looking for a flexible **plastic sheet material**.

Product Description

Our **PVC plastic sheet** is an engineered closed-cell PVC material designed for high-performance industrial and commercial applications. The product range, including **3mm, 4mm, 5mm, 6mm, 9mm, and 10mm PVC foam boards**, is specifically developed to provide a lightweight, durable, and versatile substrate. It is manufactured under stringent quality controls to meet international standards, ensuring reliable performance in demanding environments. This material is an excellent alternative to wood, aluminum, and other traditional substrates, offering superior processing flexibility and environmental resistance.

The manufacturing process ensures each **PVC foam board** has a homogeneous cell structure, resulting in a consistent finish and predictable mechanical properties. Our products are compliant with ISO standards, and their technical specifications are verified through rigorous testing, confirming their suitability for applications requiring high rigidity, low flammability, and excellent thermal insulation. The closed-cell structure prevents water absorption, making it an ideal **waterproof plastic board** for high-moisture environments.

|

Application Areas

|

FAQ

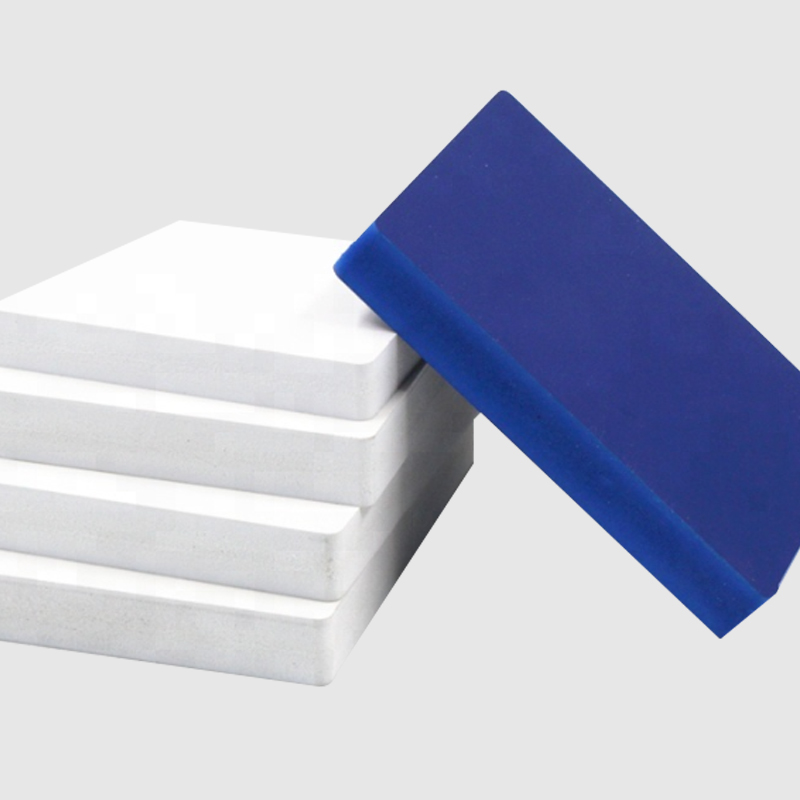

Q: What is the difference between a rigid PVC foam sheet and a Celuka PVC foam sheet?

A: A **rigid PVC foam sheet** (or free foam board) has a uniform density throughout its thickness, giving it a porous core and a matte surface. A **Celuka PVC foam sheet** is manufactured using a specific process that creates a harder, solid outer skin while retaining a cellular core. This results in a product with a superior surface hardness, better screw retention, and enhanced resistance to scratches and dents, making it more suitable for furniture and high-impact applications.

Q: How can I ensure proper adhesion when printing on a white PVC foam board?

A: To achieve optimal adhesion on **white PVC foam board**, it is recommended to clean the surface with isopropyl alcohol to remove any oils or dust. For UV printing, a specific primer might be necessary depending on the ink and the desired durability. For solvent and screen printing, no special preparation is typically needed as the surface of the PVC foam is highly receptive to these inks.

Q: Is this product suitable for long-term outdoor use?

A: Yes, our **PVC foam sheet** is highly resistant to weathering, moisture, and UV radiation, making it suitable for long-term outdoor applications. It does not rot, warp, or delaminate under exposure to environmental elements. However, for applications with extreme sun exposure, UV-stabilized grades or protective coatings are recommended to prevent potential discoloration over extended periods.

English

English Español

Español عربى

عربى