High-tech Durable 5mm PVC Foam Board Technical Plastic Sheets - High Rigidity Lightweight Engineering Material Solution

Product Features

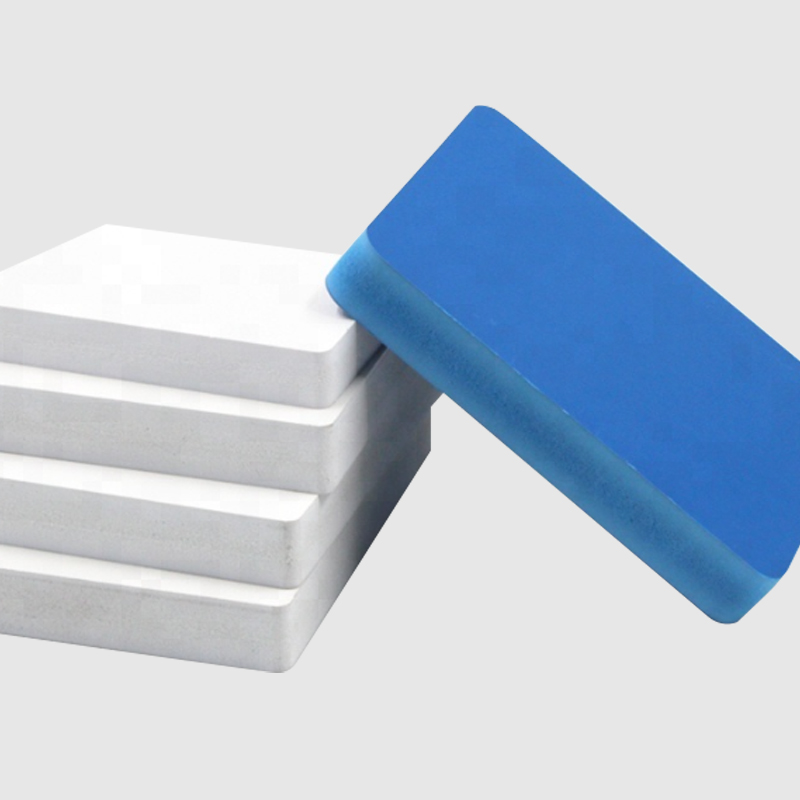

- Exceptional Strength-to-Weight Ratio: Closed-cell foam structure provides high rigidity while maintaining extremely light weight, making it an ideal lightweight PVC sheet alternative to traditional wood and metal.

- Excellent Weather and Chemical Resistance: Offers outstanding resistance to moisture, oils, acids, alkalis, and many solvents, ensuring long-term stability in harsh environments and reliable chemical-resistant PVC board performance.

- Easy to Process and Customize: Can be cut, engraved, drilled, milled, and heat-bent using standard woodworking tools, significantly simplifying the PVC foam board processing workflow and improving production efficiency.

Product Description

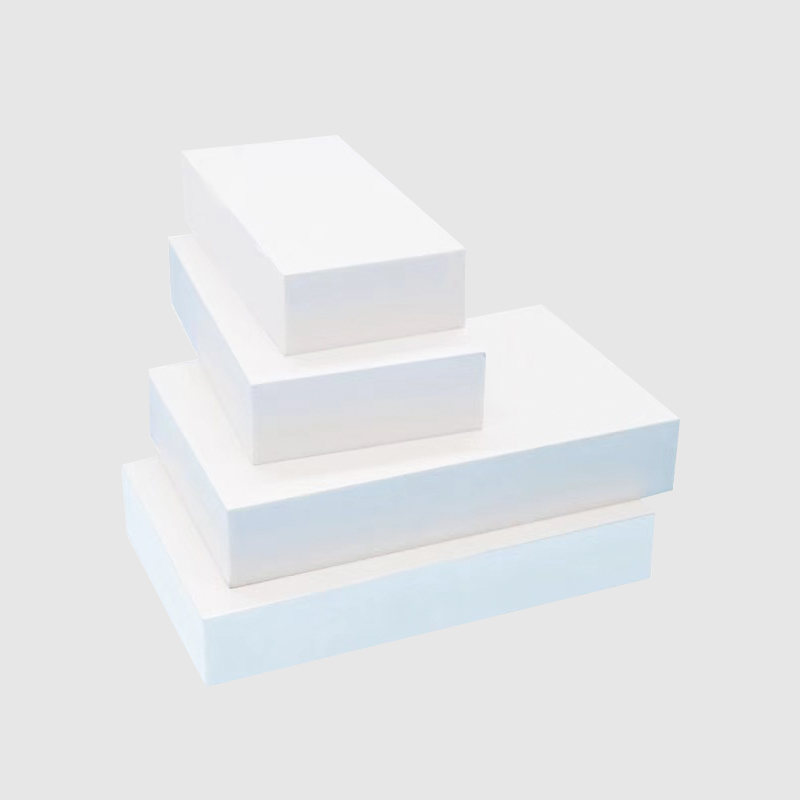

This 5mm PVC foam board is a rigid, closed-cell foam core material based on Polyvinyl Chloride, designed for industrial and commercial applications requiring lightweight properties, structural stability, and environmental resistance. Its core technology lies in the uniform microcellular foaming process, which ensures isotropic physical properties of the board, preventing warping and deformation.

The product is manufactured using pure raw materials that comply with international standards and is free of harmful substances such as asbestos. Its homogeneous structure not only provides a smooth and flat surface, facilitating subsequent laminating or printing, but also ensures aesthetic and consistent edges after cutting, meeting the high standards of commercial display material procurement needs.

Technical Specifications

| Parameter | Value | Test Standard |

| Thickness | 5mm (±0.2mm) | - |

| Density | 0.55 g/cm³ | ISO 1183 |

| Tensile Strength | ≥ 18 MPa | ISO 527 |

| Flexural Strength | ≥ 30 MPa | ISO 178 |

| Impact Strength (Charpy) | ≥ 45 kJ/m² | ISO 179 |

| Temperature Range | -20°C to +60°C | - |

| Flame Retardancy | B1 (according to DIN 4102) | DIN 4102 |

Application Fields

This product is suitable for the following industrial scenarios:

- Construction & Decoration: Outdoor sign substrate, interior decorative panels, sanitary partitions.

- Transportation: Marine interior panels, RV lining, truck body advertisement panels.

- Commercial Display: Exhibition display stands (POP display), screen printing substrate, product display cases.

- Industrial Manufacturing: Machine guards, jig pads, cleanroom panels.

Common Procurement Inquiries

1. How to choose between PVC foam board, acrylic board, or aluminum composite panel for outdoor signage applications?

The choice depends on budget, durability, and aesthetic requirements. PVC foam board is cost-effective, lightweight, and fully waterproof throughout its material, preventing core corrosion which can occur in aluminum composite panels. It is more flexible than acrylic and more impact-resistant, less prone to cracking. However, for applications requiring very high surface gloss and transparency, acrylic remains the preferred choice. If you need to select the most suitable material for your outdoor advertising signage project, our technical team can provide a comparative analysis based on your specific operating conditions.

2. After long-term outdoor use, will the surface easily yellow or will the strength decrease?

This product's formulation includes UV stabilizers to effectively delay yellowing and aging caused by sunlight exposure. Its chemical structure is stable, and strength will not decrease due to moisture absorption, which is a core advantage over wooden materials. However, under extremely intense and continuous sunlight, any polymer material will undergo slow aging. If your project has extremely high requirements for long-term color stability, it is recommended to apply a UV-protective laminate or choose white or other light-colored boards. We can provide more detailed weathering test data for your reference.

3. When performing CNC milling, how to optimize parameters to prevent burrs or tearing at the board edges?

Burrs are often related to the processing tools and parameter settings. It is recommended to use sharp, carbide milling tools with three or more teeth specifically designed for plastic processing, employing a strategy of high rotational speed and slow feed rate. Air cooling is preferable to liquid cooling to prevent the board from absorbing moisture. The optimal spindle speed, feed rate, and cutting depth depend on the specific machine and tool size. We can provide customers with a basic CNC machining guide for PVC boards and recommend conducting a sample test before mass production to optimize parameters.

English

English Español

Español عربى

عربى