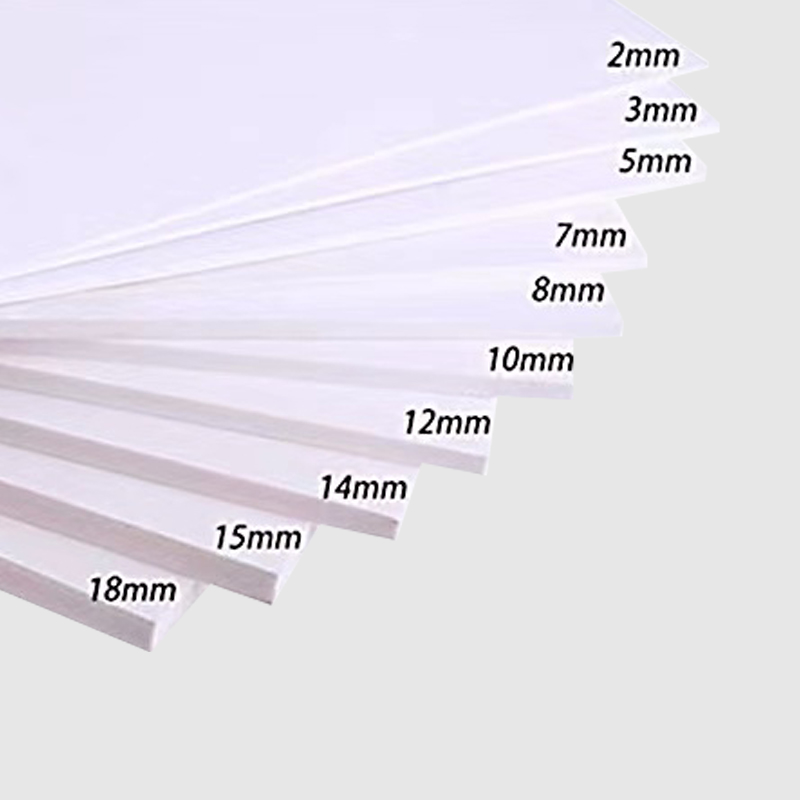

3-30mm PVC Foam Board 1220*2440mm - Versatile and Durable Plastic Sheet Solution

Product Features

- Density and Weight: Our foam boards offer a consistent, low-density core, which significantly reduces the material's weight, making it an excellent choice for applications requiring lightweight materials without compromising structural integrity.

- Durability and Longevity: The boards are engineered for exceptional resistance to moisture, rot, and chemicals. This makes them suitable for use in high-humidity environments and long-term exterior applications where conventional materials may degrade.

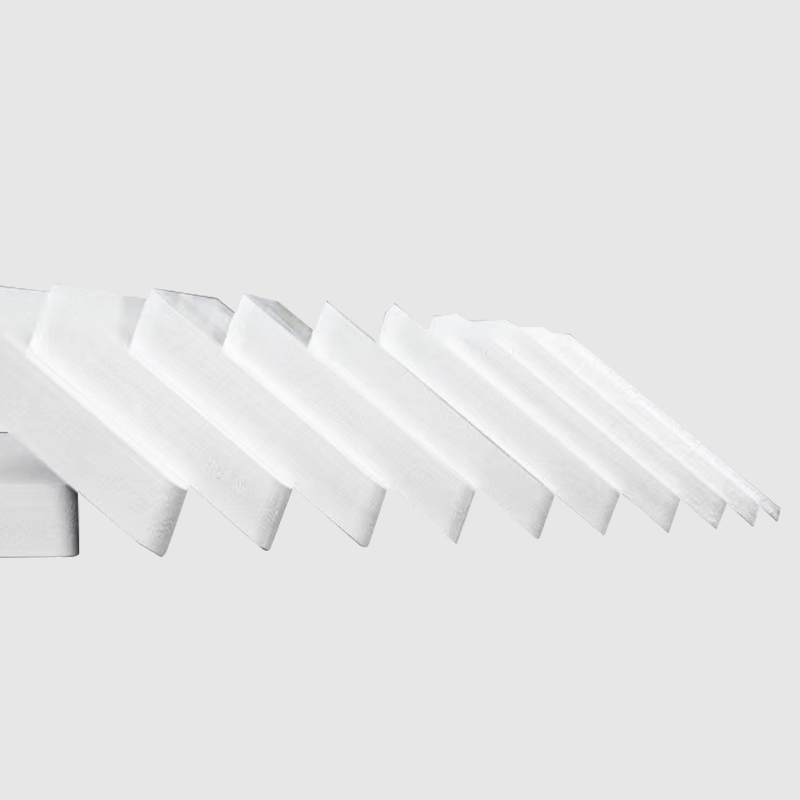

- Workability and Finishing: This material can be easily cut, sawed, drilled, and fabricated using standard tools. Its smooth surface is optimized for printing, painting, and lamination, allowing for high-quality finishing and customization.

Product Description

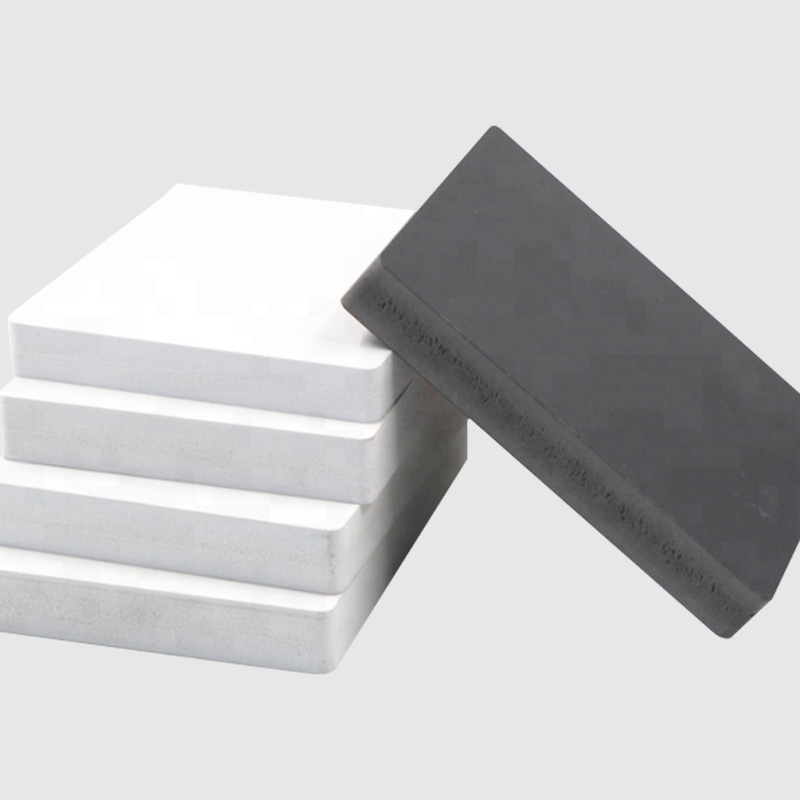

Our 3-30mm PVC foam board, available in the standard sheet size of 1220*2440mm, is a high-quality, engineered material designed to meet the demands of various industrial and commercial applications. Manufactured through a process that creates a uniform cellular structure, this product combines the robust physical properties of PVC with a lightweight foam core. It serves as a reliable and cost-effective alternative to wood, plywood, and other traditional sheet materials. This PVC free foam sheet is non-toxic, lead-free, and produced under strict quality controls to ensure consistent performance.

The product's technical advantages include its exceptional dimensional stability, resistance to fire (self-extinguishing), and excellent thermal and sound insulation properties. It adheres to international manufacturing standards, ensuring reliable performance across a variety of demanding environments. The boards are supplied to meet specific requirements for both high-density and low-density applications, making them a versatile choice for a wide range of professional projects.

Application Areas

This product is a preferred material for a wide array of industrial and commercial sectors:

- Advertising and Signage: Ideal for indoor and outdoor sign boards, display stands, exhibition booths, and digital printing. Its smooth surface allows for high-resolution graphics.

- Furniture and Cabinetry: A durable and waterproof choice for kitchen cabinets, bathroom vanities, and other furniture, particularly in areas exposed to moisture.

- Construction and Decoration: Used for wall cladding, partitions, ceilings, decorative panels, and formwork due to its moisture resistance and ease of installation.

- Industrial and Chemical: Utilized for chemical tank liners, control panels, and laboratory equipment where chemical resistance is a critical factor.

FAQ

Q1: What are the key differences between a PVC celuka board and a PVC free foam board?

A1: PVC free foam board has a uniform, low-density cellular structure throughout its thickness, resulting in a lighter weight. PVC celuka board, on the other hand, is manufactured with a hard outer skin and a lower-density foam core. This gives celuka board a more rigid and durable surface, making it better suited for applications requiring high surface hardness and scratch resistance, such as furniture.

Q2: Is this PVC foam board suitable for outdoor use?

A2: Yes. The material is inherently resistant to moisture, UV radiation (in some grades), and a range of chemicals, making it highly durable for outdoor use. However, for long-term outdoor applications, it is recommended to use PVC foam boards with a high-density formula or UV-stabilized additives to prevent discoloration and material degradation over time.

English

English Español

Español عربى

عربى