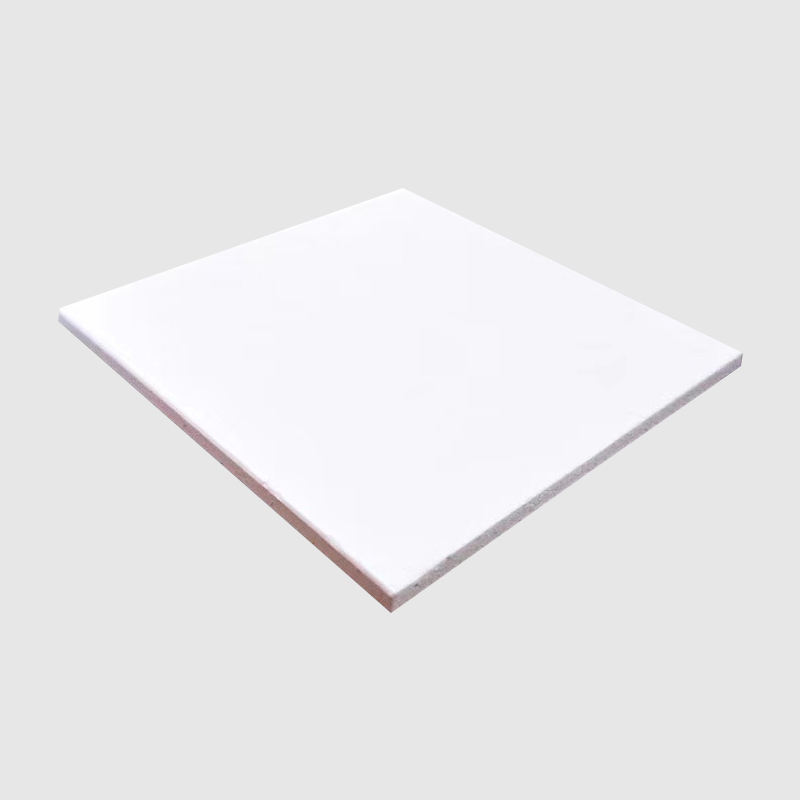

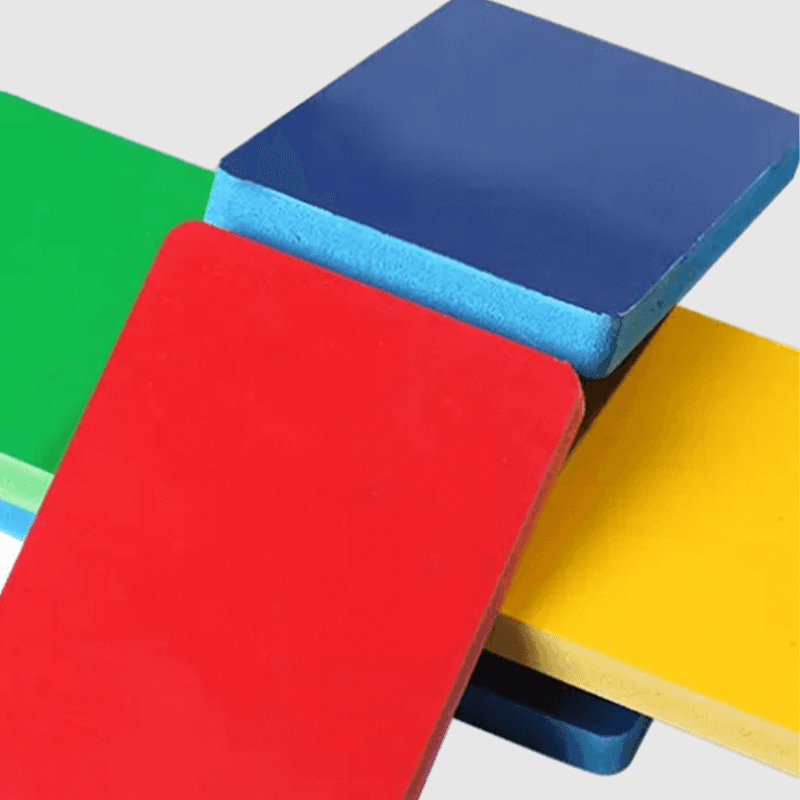

Glossy Rigid Foam Sheet White 18mm PVC Embossed Board - High-Density Structural Material for Durable Furniture Manufacturing

Product Features

- 18mm High-Density Structure: Provides exceptional rigidity and impact resistance, suitable for load-bearing furniture components.

- PVC Foam Core with Glossy Embossed Surface: Achieves a non-porous waterproof characteristic while enhancing surface aesthetic texture.

- CNC Machining Adaptability: Supports precision milling, cutting, and engraving without edge chipping, optimizing custom furniture production processes.

Product Description

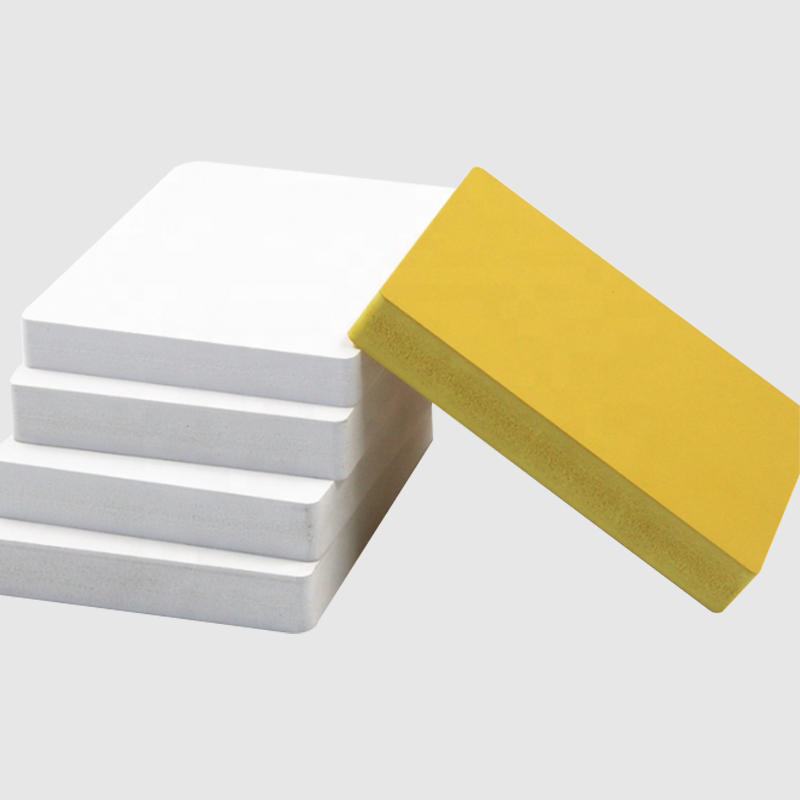

This product is a professional-grade PVC foam board manufactured by co-extruded of solid polyvinyl chloride and chemical foaming agents. Its closed-cell structure effectively blocks moisture penetration, making it primarily applicable in commercial furniture and interior decoration fields with strict hygiene standards and durability requirements.

The manufacturing process complies with the ISO 9001 quality management system, and the product is REACH certified. Technical advantages are reflected in thermal stability (deformation rate < 0.5% under operating conditions from -10°C to 60°C) and UV resistance (ΔE < 3 after 500 hours of xenon lamp testing).

Technical Specifications

| Parameter | Unit | Standard Value |

| Material Composition | - | 100% Virgin PVC |

| Standard Thickness | mm | 18±0.3 |

| Panel Size | mm | 1220x2440/1525x3050 |

| Density | kg/m³ | 550-600 |

| Rockwell Hardness | R scale | 105 |

| Flame Rating | UL94 | V-0 |

| Heat Deflection Temperature | ℃ | 65 |

Applications

This product is suitable for the following industrial scenarios:

- Moisture-proof cabinet doors for commercial kitchens

- Chemical-resistant worktops for laboratories

- Antibacterial partition systems for medical facilities

- Custom display cases for high-end retail

- Waterproof furniture for marine interiors

Common Procurement Inquiries

1. How does 18mm PVC foam board compare to MDF in cabinet manufacturing performance?

The 18mm PVC foam board significantly outperforms Medium-Density Fiberboard (MDF) in moisture resistance (water absorption < 0.5%) and antibacterial properties. Its dimensional stability maintains an expansion rate of < 0.8% in fluctuating humidity environments, whereas MDF typically exhibits > 15%. For applications requiring frequent cleaning or high humidity conditions, PVC foam board eliminates the risk of panel expansion and deformation. Specific material selection should be based on your budget and operational requirements; our technical team can provide free samples for comparative testing.

2. Does the embossed surface affect subsequent UV printing or laminating processes?

The embossed depth of this product is precisely controlled within the range of 0.15-0.25mm, matching the ink droplet penetration depth (0.2mm) of mainstream UV flatbed printers. The surface undergoes corona treatment to achieve 52 dyne value, ensuring ink adhesion meets ISO Class 5 standards. For laminating applications, acrylic adhesive films with viscosity ≥25g/25mm are recommended. For specific process parameters, you can request our Surface Treatment Technical White Paper.

3. Will the board become brittle in low-temperature environments?

The PVC core material, formulated with modified toughening agents, has a glass transition temperature (Tg) reduced to -25°C. In impact tests at -10°C, the Izod notched impact strength remains ≥25kJ/m² (ASTM D256 standard). For actual installation, the ambient temperature is recommended to be no lower than -5°C, and low-temperature专用 cutting tools should be used. For extreme environment applications, we can provide custom low-temperature formulation solutions.

English

English Español

Español عربى

عربى