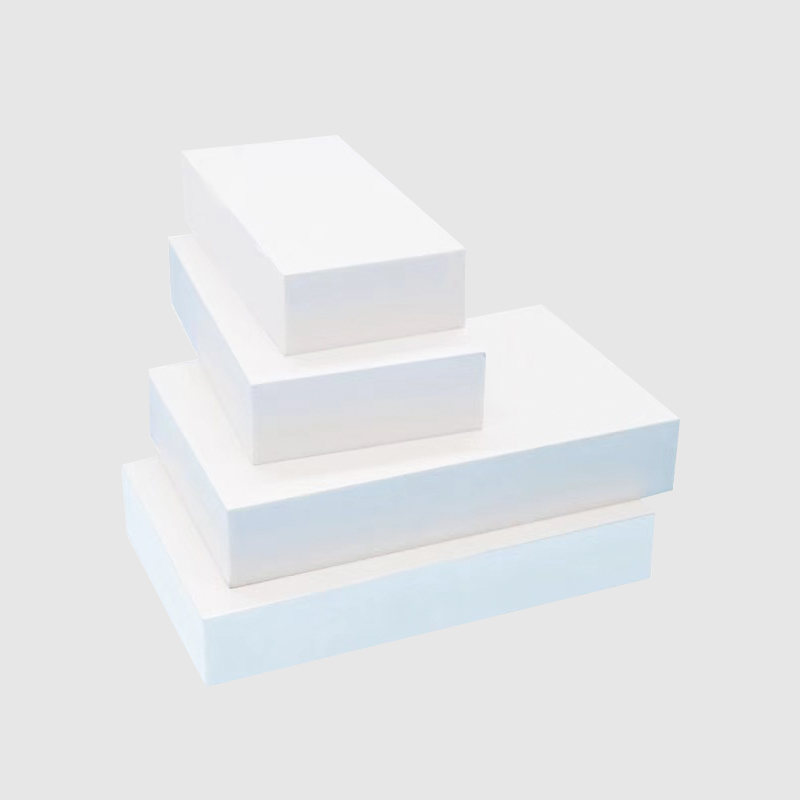

High Density PVC Foam Board - Rigid Substrate for Advertising and Construction

Product Characteristics

- Density Consistency: Manufactured to achieve a **high density specification**, providing enhanced rigidity and mechanical strength suitable for structural applications and **load-bearing advertising displays**.

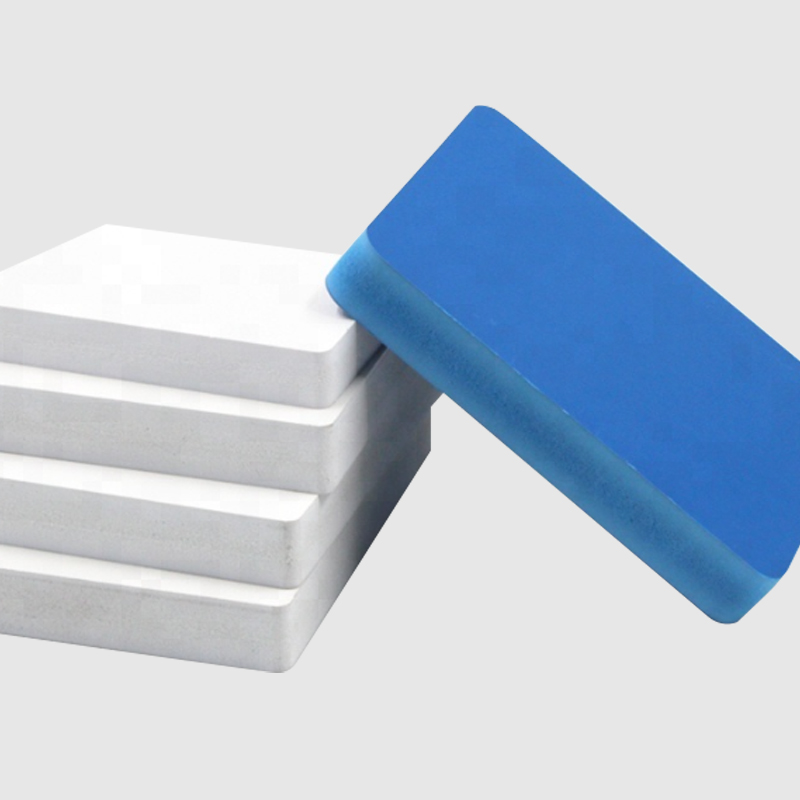

- Surface Finish: Features a smooth, uniform surface that is receptive to various printing techniques, including **UV digital printing and screen printing**, making it an effective substrate for **PVC sheet printing applications**.

- Material Composition: Utilizes polyvinyl chloride (PVC) as the base polymer, offering inherent **chemical resistance** and **moisture resistance**, making it suitable for both indoor and outdoor **signage materials**.

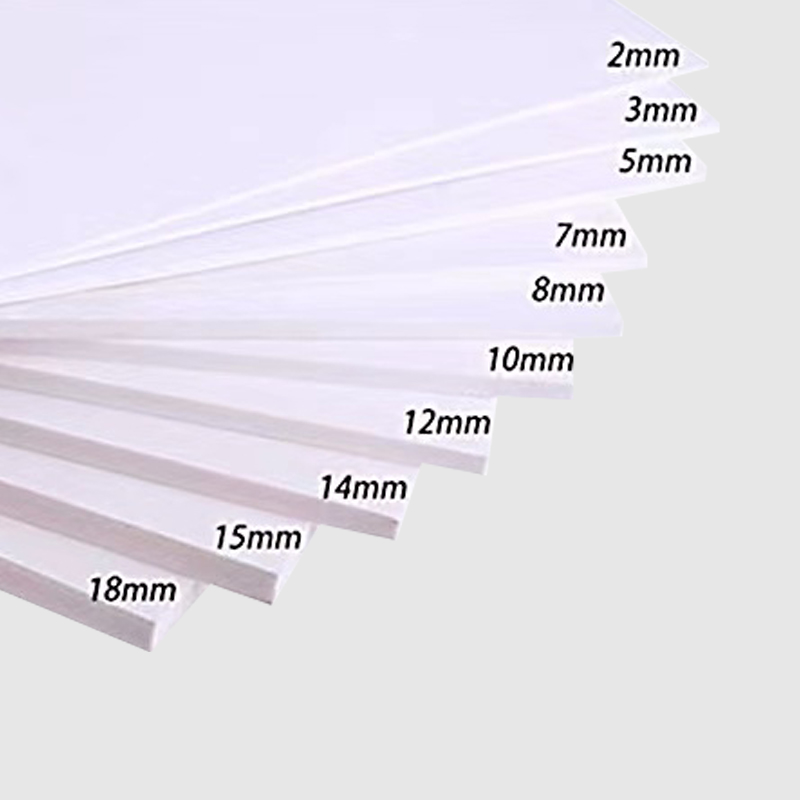

- Processing Versatility: The material can be easily cut, routed, sawed, and drilled using standard tools, facilitating complex fabrication for **custom celuka board displays** and **exhibition stand construction**.

- Flame Retardancy: Exhibits properties that contribute to **fire safety compliance**, a mandatory requirement for interior applications such as **building decoration boards** and public advertising spaces.

Product Description

The product's uniform thickness and consistent density across batches make it a reliable choice for **B2B manufacturers** requiring predictable material performance. Its inherent characteristics of being lightweight yet rigid, combined with moisture and chemical resistance, position it as a technical alternative to wood or other composite boards in areas where longevity and environmental resistance are crucial, such as **outdoor display fabrication** and **transportation industry interior decoration**. **Jiatao Industrial Co., Ltd.** is committed to the production of **polyvinyl chloride plastic board** using advanced processes to maintain this standard.

Technical Specifications

| Parameter | Typical Range/Detail | Key Performance Attribute |

| Material Composition | Polyvinyl Chloride (PVC) | **Chemical & Water Resistance** |

| Density Classification | High Density (Specific GSM/CC) | Rigidity and Strength |

| Manufacturing Method | Advanced Extrusion / Celuka Process | Surface Hardness and Consistency |

| Sheet Thickness (mm) | 3mm to 30mm (Customizable) | Structural Depth |

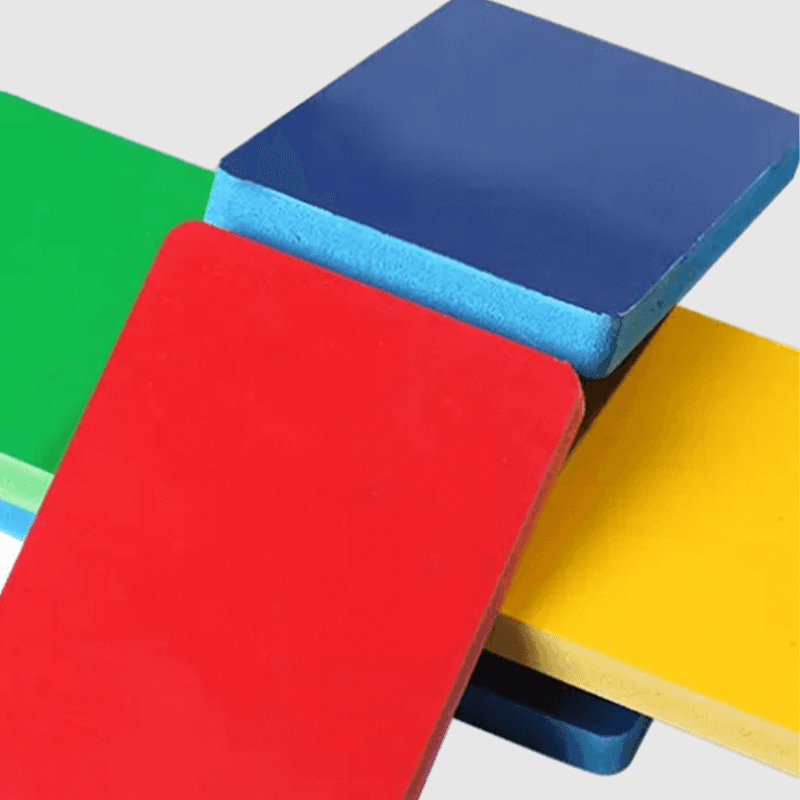

| Color Availability | White (Standard) & Custom Colors | Aesthetic Customization |

| Fire Behavior | Self-Extinguishing Properties | Safety Compliance |

Application Scenarios

This substrate is sought after by B2B buyers across various industries requiring durable, lightweight, and printable sheeting materials:

- **Advertising and Signage Industry:** Used for point-of-sale displays, large format signage, exhibition stands, and **outdoor billboard substrates**.

- **Building Decoration Industry:** Employed for interior wall cladding, partitions, kitchen cabinets, and **moisture-resistant bathroom paneling**.

- **Furniture Industry:** Applied in the manufacture of lightweight furniture components, storage boxes, and specialty **PVC foam furniture parts**.

- **Transportation Industry:** Used for interior decorative panels and non-structural components in vehicles, due to its **fire resistance and low weight**.

FAQ

- What is the difference between standard PVC foam board and Celuka foam board, and which application is this high-density board best suited for?

- Celuka foam board, which this high-density product often utilizes, is produced using a specific process that creates a harder, denser outer "skin" compared to the internal foam core. This results in superior surface hardness, better screw retention, and enhanced resistance to dents and scratches. This high-density board is best suited for applications requiring high durability and a smooth printing surface, such as **permanent POP displays**, **cabinetry**, and **exterior signage**, where structural integrity and longevity are prioritized by the **advertising and furniture industries**.

- How does Jiatao Industrial ensure the batch-to-batch consistency of the PVC foam density and thickness?

- Ensuring consistency is vital for our global customer base, which includes over 10 of the world's top 500 enterprises in sectors like advertising and building decoration. **Jiatao Industrial Co., Ltd.** employs advanced extruded technology and precise cooling solidification processes in our large-scale production base. Our commitment to the **high-grade and high-end market** is supported by strict process control and monitoring systems that regulate polymer flow and temperature, which are key to maintaining the uniform cell structure and predictable density of the **PVC foam board sheets**. We can produce more than 25,000 tons of PVC plate annually, ensuring consistent quality for our customers in the US, Germany, Japan, and other countries.

- What export capabilities and geographical reach does Jiatao Industrial offer for B2B distributors?

- **Jiatao Industrial Co., Ltd.** operates as an important supplier of PVC board in China with established global export channels. Our products are mainly exported to dozens of countries across North America, Europe, and Asia, including the United States, Germany, Japan, Spain, Italy, Britain, South Korea, Australia, and Canada. Our team is focused on development, production, and sales to ensure the best possible service for our customers worldwide. We provide reliable supply chain solutions for **extruded foam board manufacturers** and B2B cooperation customers in sectors like building decoration and transportation industry interior decoration.

English

English Español

Español عربى

عربى