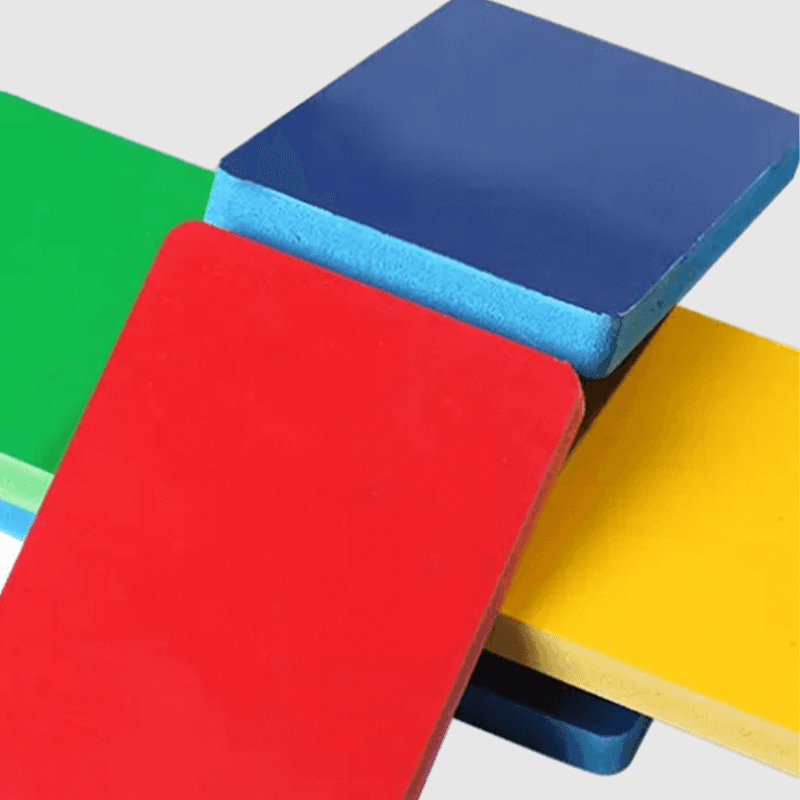

3-25mm Thickness 0.4-0.9g/cm3 Density 1220mm x 2440mm PVC Celuka Foam Board - High-Performance Rigid PVC Foam Sheet for Industrial Applications

Product Characteristics

- Celuka Production Process: Manufactured using Celuka co-extruded technology, resulting in a dense, smooth surface and a uniform closed-cell foam core, providing excellent surface printability and machinability.

- Lightweight with High Density Ratio: Density range from 0.4g/cm³ to 0.9g/cm³ ensures structural strength while achieving material lightweighting, helping to reduce overall shipping and material costs.

- Excellent Weather and Chemical Resistance: This product exhibits outstanding resistance to acids, alkalis, salts, and various chemicals, is non-hygroscopic, and resistant to mold, making it suitable for various harsh environments.

Product Description

This product is a rigid PVC foam board manufactured using advanced Celuka foaming technology. Its core design is to provide an engineering material that combines lightweight, high strength, and exceptional weather resistance for the construction, advertising, transportation, and industrial manufacturing sectors. The board features a highly uniform closed-cell structure, ensuring consistent physical properties and ease of processing, suitable for secondary operations such as CNC milling, cutting, heat bending, and bonding.

Our PVC Celuka foam boards adhere to strict production standards, ensuring quality control from raw materials to finished products. Their stable performance makes them an ideal alternative to traditional materials like wood, metal, or ordinary composites, particularly suited for applications requiring weight reduction while maintaining high strength.

Technical Specifications

| Parameter | Specification/Value | Notes |

| Product Type | PVC Celuka Foam Board | Rigid Closed-Cell Foam |

| Standard Size | 1220 mm x 2440 mm | Custom sizes available |

| Thickness Range | 3mm - 25mm | Specific thicknesses available |

| Density Range | 0.4 g/cm³ - 0.9 g/cm³ | Multiple options |

| Surface Finish | Smooth | Suitable for direct painting and laminating |

Application Areas

This product is suitable for the following industrial scenarios:

- Construction & Decoration: Used for exterior wall cladding, interior partitions, decorative trims, and ceilings.

- Advertising & Display: Serves as a substrate for large-format printing, exhibition panels, and high-end signage.

- Transportation: Used for interior panels, wall panels, and cabinet manufacturing in buses, trains, and ships.

- Industrial Manufacturing: Used as CNC machining material for jigs, fixtures, models, and templates.

Frequently Asked Procurement Questions

1. How to choose the right density of PVC foam board for outdoor signage projects?

The choice of density primarily depends on the requirements for mechanical strength and wind load resistance. For large outdoor signage, boards with a density of no less than 0.55g/cm³ are recommended to ensure sufficient rigidity. If the sign structure includes reinforcing supports, a lower density can be considered to control costs. The final selection should be based on your specific design, installation environment, and budget. Our technical team can provide a free selection analysis for your project.

2. What is the difference between PVC Celuka board and ordinary PVC foam board with laminated surface after CNC processing?

The main difference lies in the edge quality after machining. The uniform closed-cell structure formed by the Celuka process allows it to produce smooth, non-granular edges after CNC milling or engraving, requiring almost no secondary sanding. In contrast, the edges of ordinary foam boards with laminated surfaces may be rougher. This makes Celuka board more efficient and higher quality for producing high-end display props and parts requiring fine details.

3. Will this board warp or delaminate when used long-term in damp environments?

No. Thanks to its 100% closed-cell structure and the inherent water-repellent nature of PVC material, this product absorbs almost no moisture (water absorption is typically below 1%). Therefore, it will not swell, warp, or delaminate due to moisture absorption. This characteristic makes it highly suitable for use in humid environments or those with significant temperature variations, such as bathroom furniture, cleaning rooms, and cold storage, solving the core pain point of traditional wood being prone to moisture damage and rot.

English

English Español

Español عربى

عربى