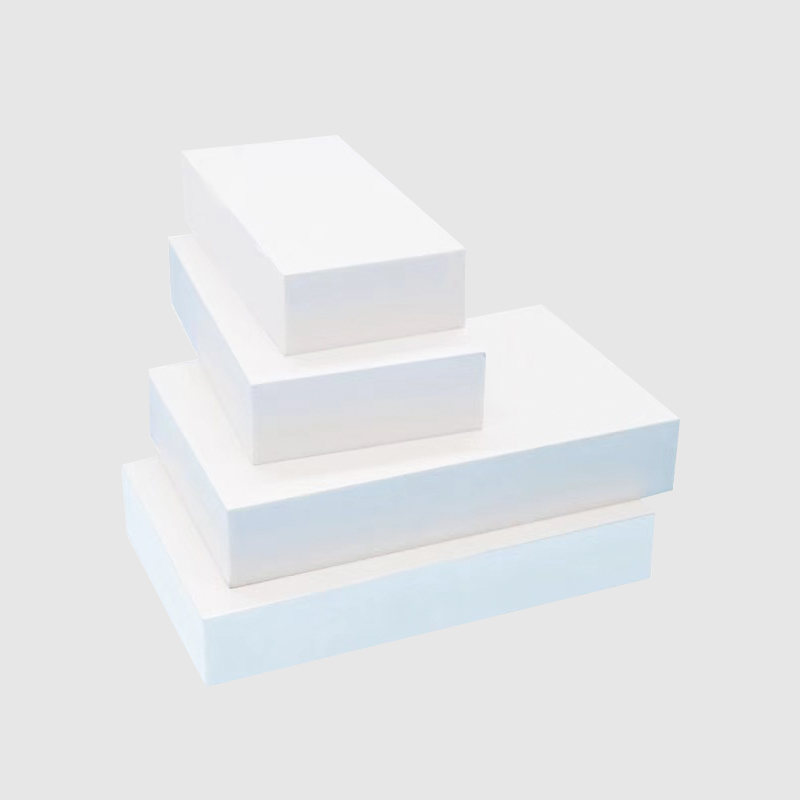

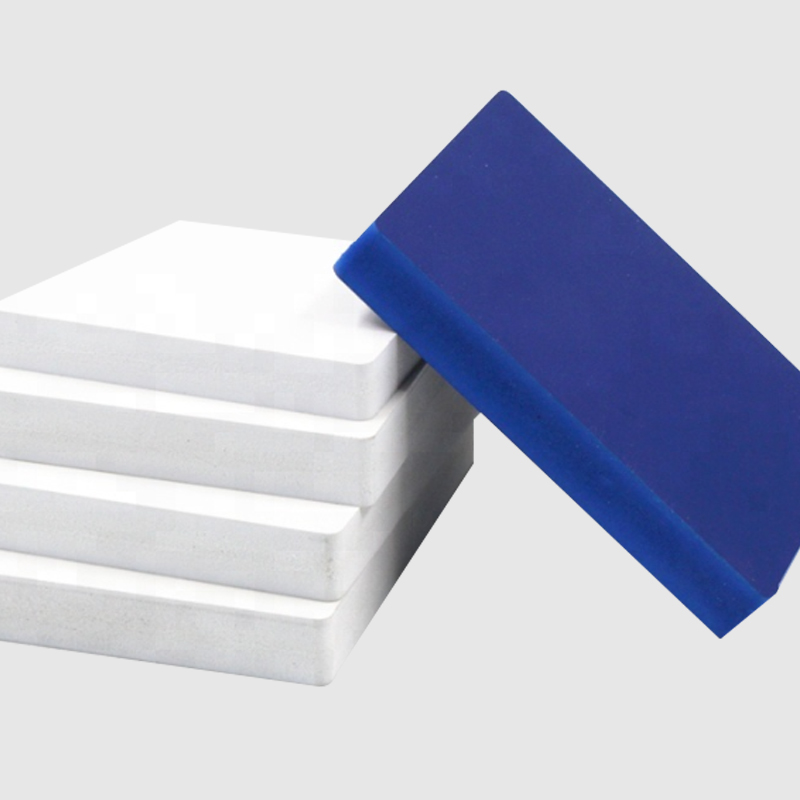

13mm Waterproof WPC 1220x2440 1220x1830mm Fireproof WPC/PVC Foam Board - A Durable and Versatile Building Panel Solution

Product Features

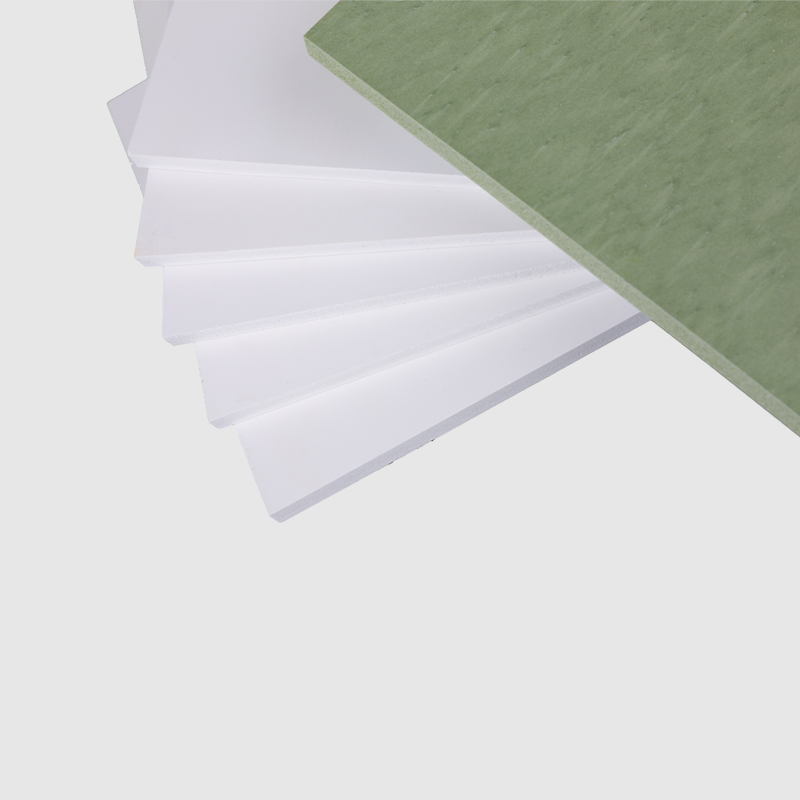

- Excellent Waterproof and Moisture-Resistant Performance: Utilizing a WPC/PVC foam core and high-density surface layer, it provides an exceptional waterproof barrier, completely preventing issues like swelling, deformation, or mildew caused by moisture penetration. It is an ideal material for high-humidity environment applications.

- High-Class Fire Retardant Properties: The product complies with stringent fire safety standards, offering excellent flame-retardant characteristics. It effectively slows the spread of fire, enhancing overall safety in construction projects and meeting codes for commercial and industrial buildings.

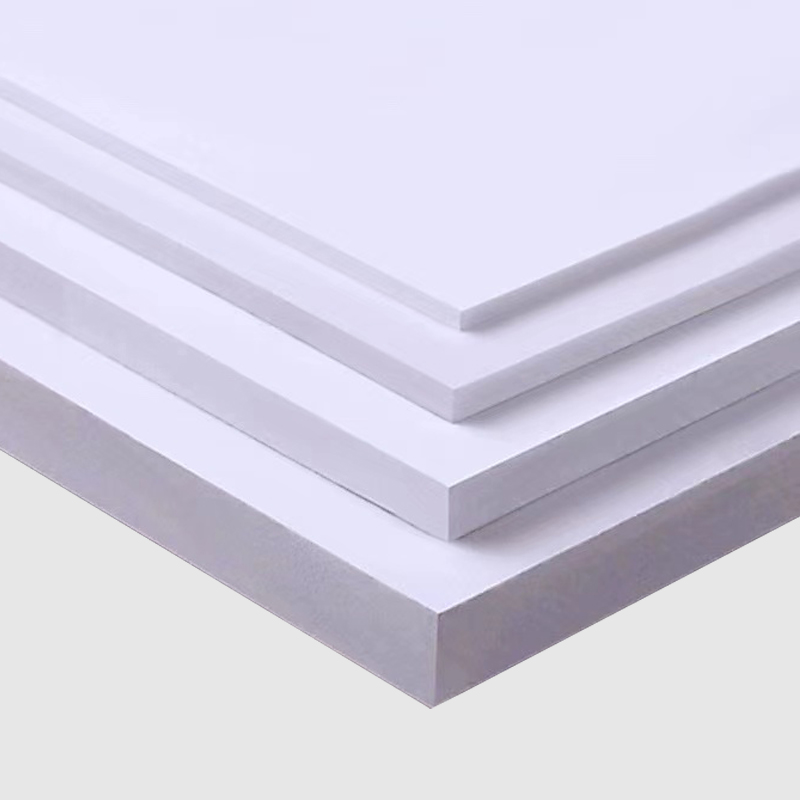

- Structurally Stable and Easy to Fabricate: The board offers high strength and impact resistance while being lightweight. It is easy for on-site cutting, drilling, and installation, compatible with standard woodworking tools, significantly improving construction efficiency and reducing project installation costs.

Product Description

This product is an advanced Wood-Plastic Composite (WPC) and PVC Foam Board, designed specifically for demanding industrial and commercial environments. Its core employs a closed-cell foam structure, co-extruded with a robust surface layer to form a composite panel that combines light weight, high strength, and superior environmental resistance. This technology ensures dimensional stability and a long lifecycle under various climatic conditions.

The board is manufactured in strict accordance with international quality systems, and its performance parameters are verified through laboratory testing. It represents a reliable alternative to traditional wood, pure plastic, or metal panels, providing comparable or superior performance while addressing industry pain points such as susceptibility to corrosion, high maintenance costs, and poor environmental tolerance.

Technical Specifications

| Parameter | Specification/Value | Standard |

| Product Name | Waterproof WPC/PVC Foam Board | - |

| Standard Thickness | 13 mm | - |

| Standard Size | 1220 x 2440 mm; 1220 x 1830 mm | - |

| Core Material | WPC/PVC Foam | - |

| Fire Rating | B1 | GB 8624 |

| Density | 0.55 - 0.70 g/cm³ | - |

| Water Absorption | < 1% | 24h Immersion |

Application Areas

This product is suitable for the following industrial scenarios:

- Commercial interior and exterior decoration and advertising substrate production

- Ship and RV interior bulkheads and partitions

- Moisture-resistant wall panels and partitions for food processing plants and cold storage facilities

- Moisture-proof partitions and cabinets for bathrooms, shower rooms, and kitchens

- Exhibition display and shop fitting construction

Common Procurement Inquiries

1. How does the installation process for WPC foam board compare to traditional aluminum composite panel or plywood?

Installation is significantly streamlined compared to many alternatives. Our WPC foam board can be cut, routed, and drilled using standard woodworking tools, eliminating the need for specialized metalworking equipment required for aluminum composite panels. Unlike exterior-grade plywood, it requires no sealing of edges against moisture. For fixed installation, we recommend using specific adhesives and mechanical fasteners suitable for foam-based substrates. The optimal method depends on your substrate and application; our technical team can provide a free installation guideline for your project.

2. What is the expected service life and performance in constant direct sunlight and rain for outdoor signage?

The board is engineered for long-term outdoor durability. The integrated materials offer high resistance to UV radiation and moisture, preventing delamination and significant color fading. Under normal conditions, the panel maintains its structural integrity and appearance for years. For extreme weathering applications, we offer versions with additional UV-resistant coatings. We advise consulting with our engineers for a lifespan projection based on your specific geographic location and environmental conditions.

3. Can this fireproof board be used as a substrate for direct tile application in wet areas?

Yes, its waterproof nature and stable surface make it a suitable substrate for tile in wet areas like showers, provided the correct installation protocol is followed. This includes using a flexible thin-set mortar adhesive designed for use with waterproof panels and ensuring all joints are properly treated. It is a modern alternative to traditional cement board, offering easier cutting and handling. We recommend reviewing our detailed technical data sheet for tile installation to ensure long-term performance.

English

English Español

Español عربى

عربى