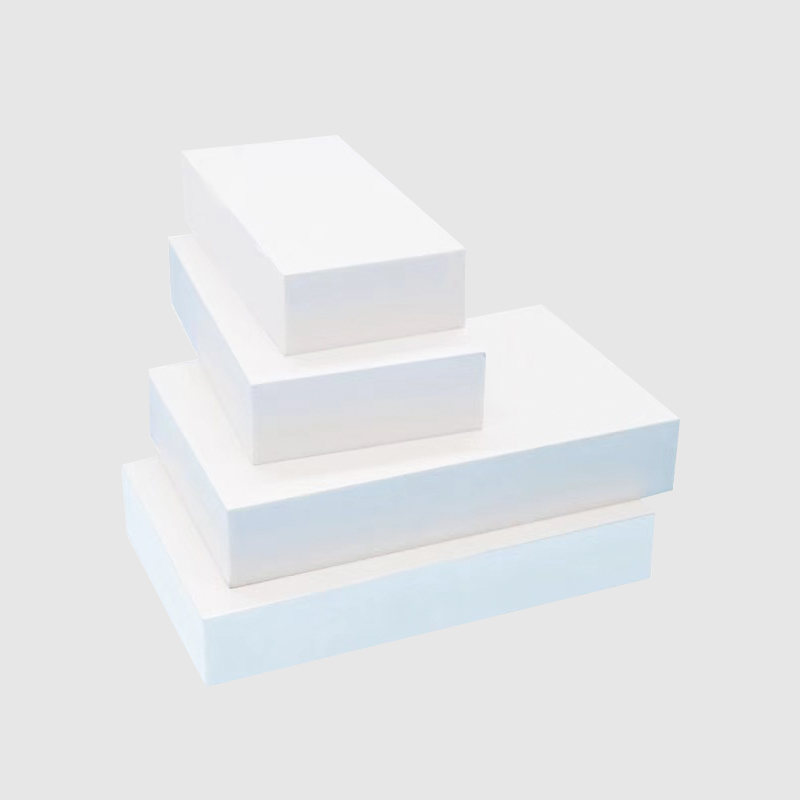

Lead-free 4mm Polyurethane Foam Board PVC Board - Professional Waterproof Advertising Building Material Panel with Smooth Surface for High-Quality Printing

Product Features

- Excellent Waterproof and Moisture-Resistant Performance: Manufactured using a composite process of dense polyurethane foam core and PVC laminate, it boasts a stable structure that effectively blocks moisture penetration, preventing deformation or degradation in damp environments. It is an ideal choice for long-term outdoor advertising displays.

- High-Smoothness Printing Surface: The panel surface is specially treated to be flat and smooth, offering even ink absorption and strong compatibility. It supports various processes like UV printing and screen printing, enabling vibrant colors and clear details for high-quality advertising graphics.

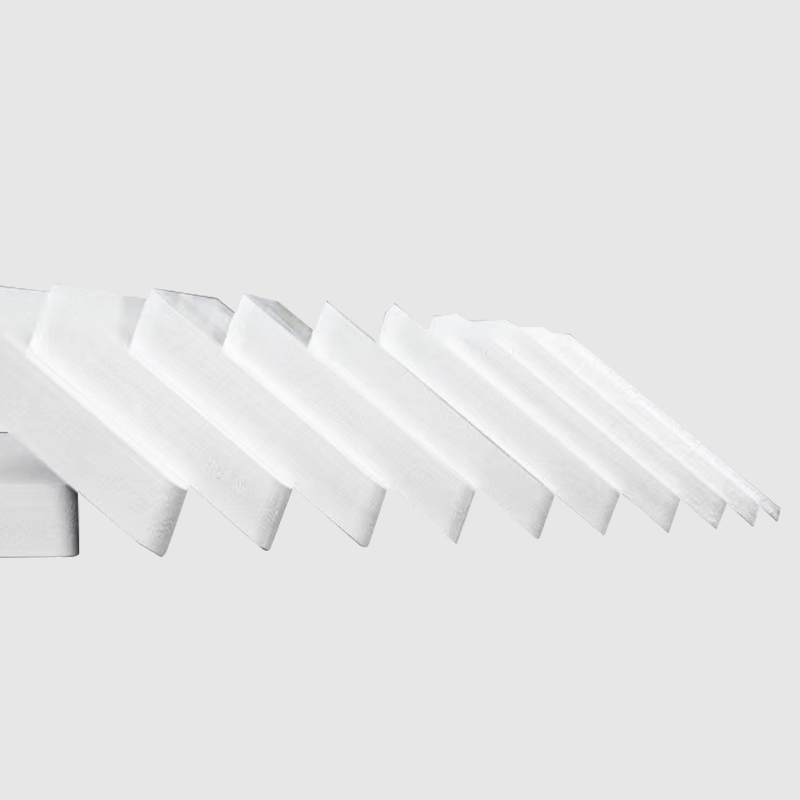

- Lightweight and Easy Processability: The product has low density and is lightweight, facilitating transportation and installation. Its uniform material is easy to cut, engrave, and mill using standard woodworking tools, significantly improving efficiency in advertising sign production.

- Eco-Friendly and Safe: This product features a lead-free formulation, complying with modern environmental standards for building materials. It is safer during production and use, suitable for indoor and outdoor applications with strict material requirements.

Product Description

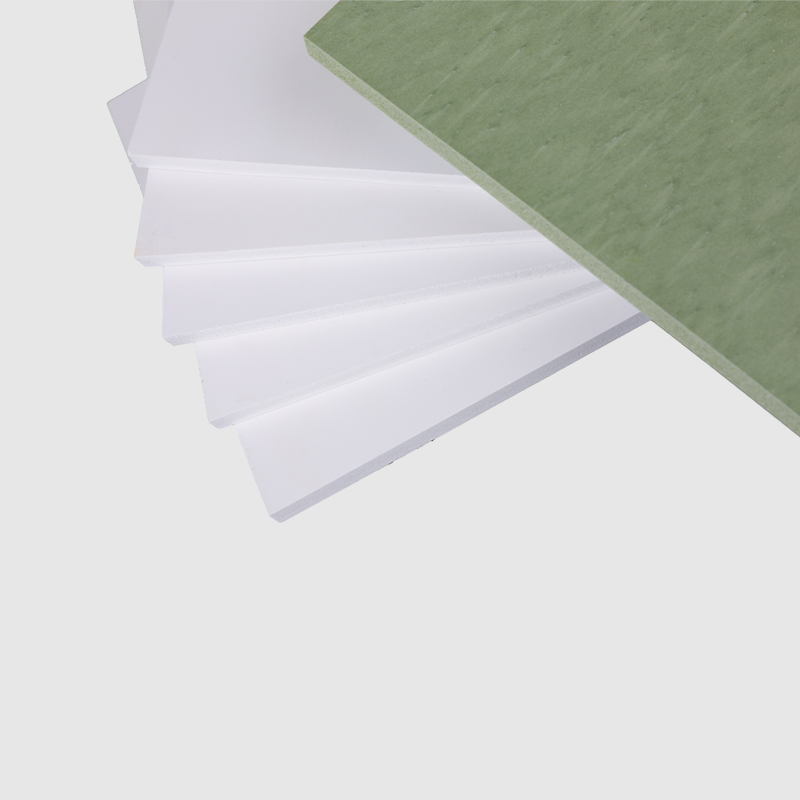

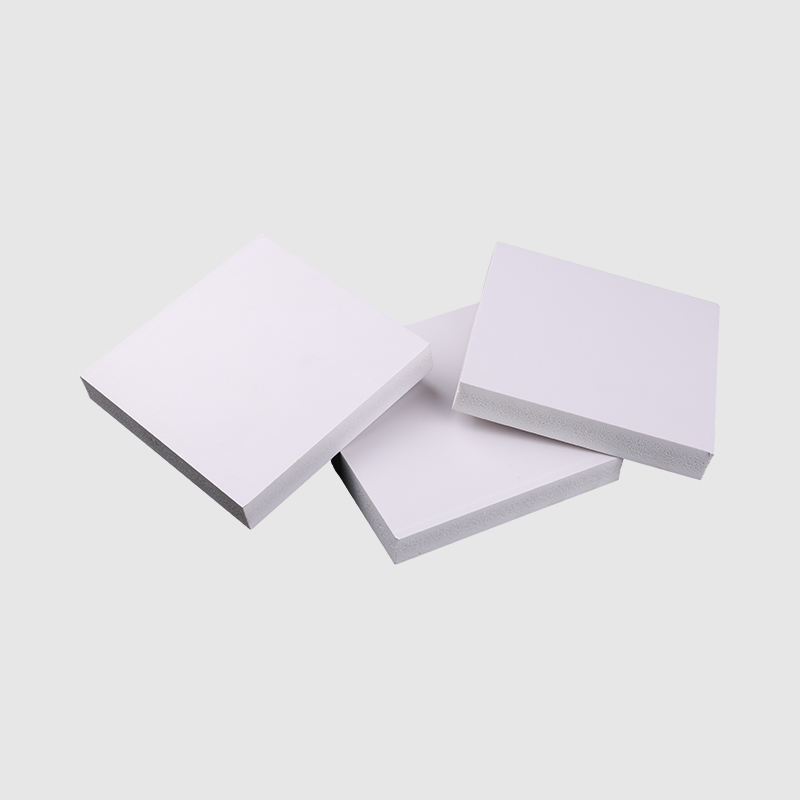

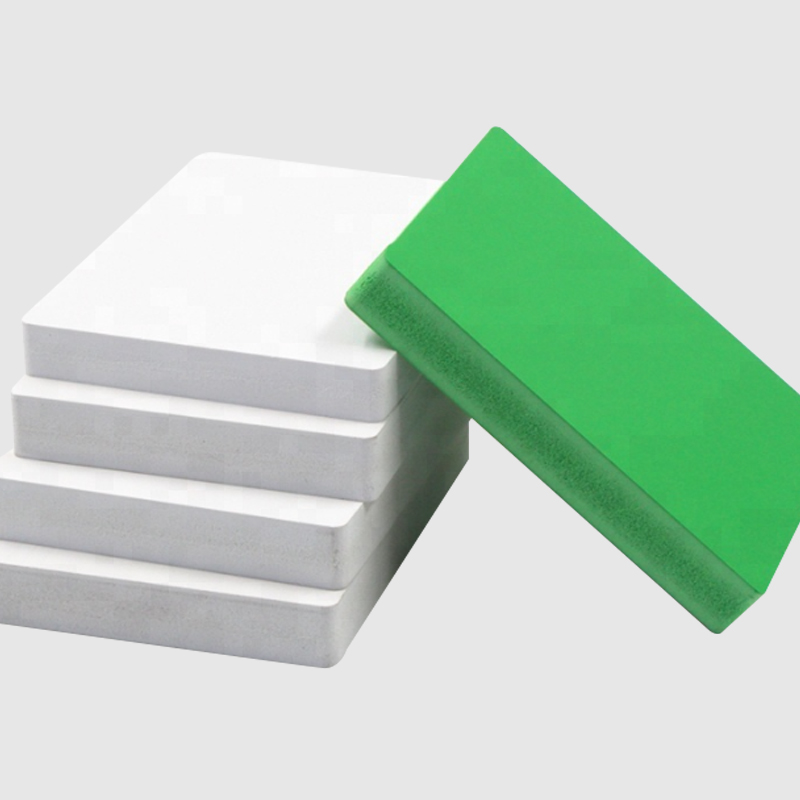

This product is a lightweight panel made by co-extruding a polyurethane (PU) foam core layer with a rigid polyvinyl chloride (PVC) laminate. It is designed to provide a functional, durable, and economical substrate solution for advertising displays, architectural interiors, and commercial signage. The core technology combines the lightweight cushioning properties of PU foam with the high rigidity and glossiness of the PVC surface.

Production strictly adheres to industry quality control systems, ensuring consistency between batches. Its outstanding physical stability allows it to adapt to various climatic conditions, while its lead-free eco-friendly properties meet the growing market demand for sustainable and safe materials.

Technical Specifications

| Parameter | Specification | Test Standard |

| Product Type | PVC Composite Foam Board | - |

| Standard Thickness | 4mm (±0.2mm) | GB/T 6342 |

| Common Size | 1220mm x 2440mm (4' x 8') | - |

| Surface Material | Rigid PVC | - |

| Core Material | Polyurethane (PU) Foam | - |

| Density | 0.55 - 0.70 g/cm³ | GB/T 6343 |

| Surface Hardness | > 90 (Shore D) | GB/T 2411 |

| Water Absorption | < 1.0% | GB/T 8810 |

| Environmental Standard | Lead-free, Complies with RoHS | - |

Application Areas

This product is suitable for the following industrial and commercial scenarios:

- Outdoor Advertising and Exhibition Displays: Used for producing outdoor billboards, exhibition panels, promotional booths, and POP displays in shopping malls. Its waterproof and weather-resistant properties ensure long-lasting visuals.

- Architectural and Interior Decoration: Applied in commercial space partitions, decorative wall panels, ceiling tiles, and store sign backings for indoor and outdoor decoration projects.

- Digital Printing and Printing Substrate: Serves as an ideal substrate for high-precision UV flatbed printing, used in creating large-format posters, vehicle wraps, and decorative art.

- Industrial Applications: Used in furniture backing, logistics packaging, and temporary partitions where lightweight panel solutions are required.

Common Procurement Inquiries

1. Compared to acrylic or PVC foam boards of the same thickness, what are the advantages of this 4mm PVC foam board in terms of outdoor durability?

Compared to acrylic boards, this product offers better impact resistance and is less prone to cracking. Compared to PVC foam boards (such as Sintra), its polyurethane core has a denser structure, providing superior waterproof and moisture-resistant performance. With extremely low water absorption (<1.0%) during long-term exposure to humid environments, it effectively avoids swelling, deformation, or loss of strength. For outdoor billboards and signs requiring long-term use, this product offers more reliable durability. The final choice depends on your budget and project requirements for rigidity and weight; our technical consultants can provide a free selection analysis.

2. The board is advertised as "easy to process." What should be noted during actual operation to prevent edge chipping?

Although this product can be cut and engraved using standard woodworking tools, to achieve smooth, burr-free edges, we recommend: using sharp, carbide-tipped high-speed router bits or double-flute spiral bits; maintain a steady and moderate feed rate, as going too fast may cause edge chipping; for fine engraving, using a CNC machine is advised for optimal precision. If you plan on large-scale processing, we can provide detailed machining parameter guidelines and tool recommendations.

3. How important is the lead-free property of this product for commercial projects exporting to European and American markets?

Being lead-free is a key requirement for complying with strict environmental directives such as the EU's RoHS and REACH. Using lead-containing materials may cause your final products to fail customs inspections, resulting in returns or fines. This product's lead-free formulation ensures compliance with these export regulations from the material source, reducing trade barrier risks for you. It is a reliable choice for international markets, high-end brands, or projects with stringent environmental requirements. If compliance documentation is needed, our sales team can provide it promptly.

English

English Español

Español عربى

عربى