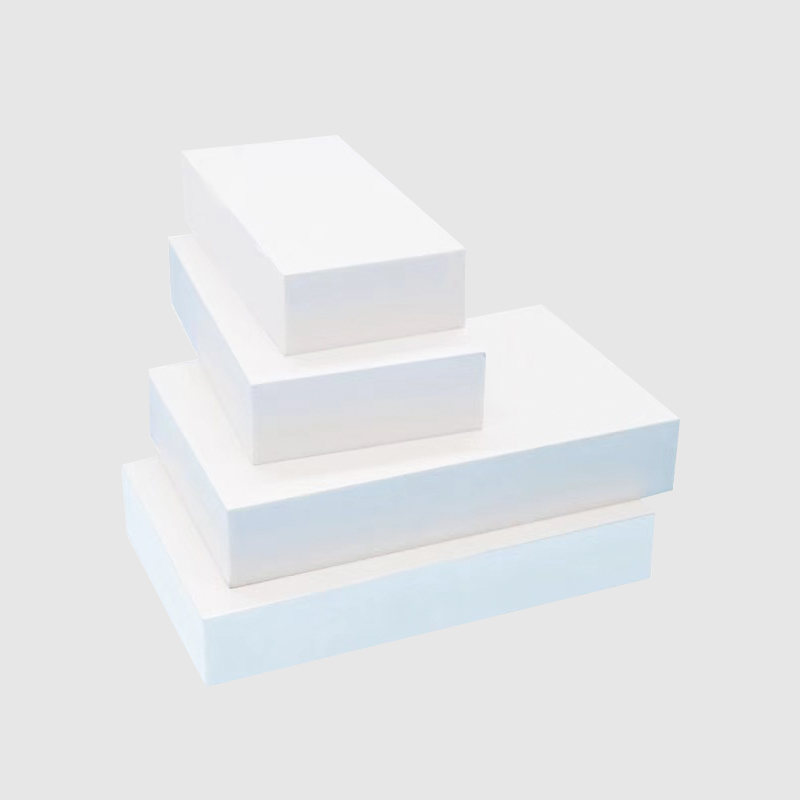

10mm White PVC Foam Board Celuka Forex Plastic Sheet: For Furniture & High-Density Wall Panels

The 10mm white PVC foam board is a rigid, lightweight closed-cell foam material produced through the Celuka process. This manufacturing method contributes to its smooth surface and consistent core density. It is used in applications requiring durability and stability, such as furniture manufacturing with PVC foam board and interior wall cladding.

Core Features and Advantages

Material Properties

- Structural Integrity: Maintains shape under mechanical stress and varying humidity conditions.

- Moisture Resistance: Does not absorb water, preventing warping or rotting.

- Workability: Can be cut, routed, and fabricated using standard woodworking tools.

- Surface Quality: Accepts common adhesives and coatings without extensive pretreatment.

Application Areas

- Exhibition stands and signage

- Interior wall and ceiling panels

- Cabinet and furniture components

- Point-of-purchase (POP) displays

- Model making and prototyping

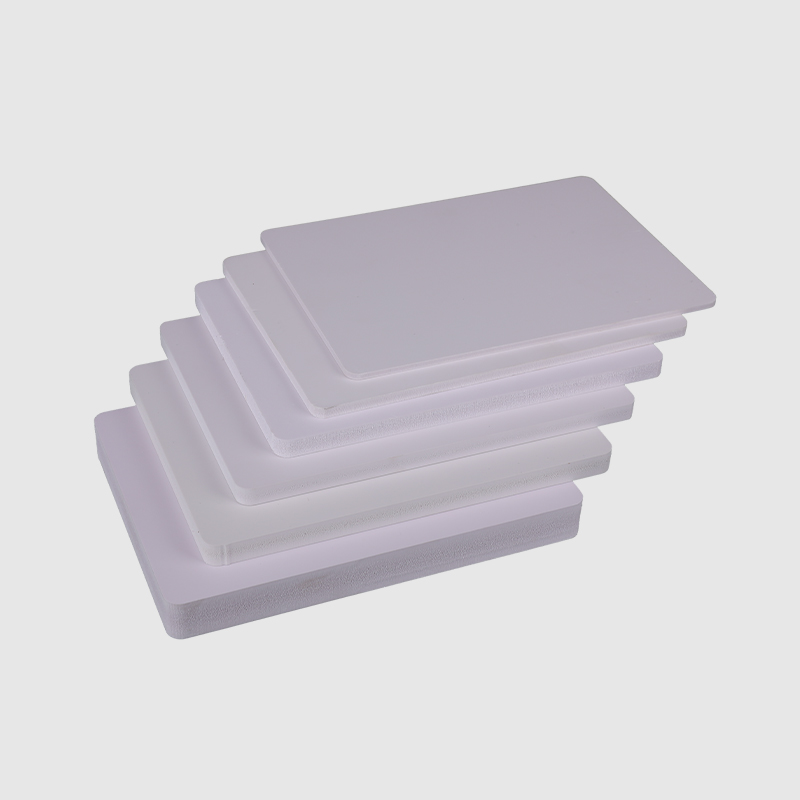

Technical Parameters

| Material Type | PVC (Polyvinyl Chloride) Foam |

| Thickness | 10mm (±0.2mm) |

| Width x Length | 1220mm x 2440mm (Standard Sheet Size) |

| Density | Approx. 0.55 g/cm³ |

| Surface Finish | Two smooth sides |

| Core Type | Celuka (Closed-cell, hard skin foam core) |

| Fire Rating | BS476 Part 7 Class 1 / B-s1,d0 (Subject to manufacturer specification) |

Frequently Asked Questions

What are the recommended methods for cutting this material?

Sheets can be cut using panel saws, CNC routers, or hand tools with fine-tooth blades. CNC machining is recommended for high-density PVC wall panel applications requiring complex shapes.

Is this material suitable for outdoor use?

Standard white PVC foam boards are intended for indoor applications. Prolonged exposure to UV light and weather elements can affect surface appearance.

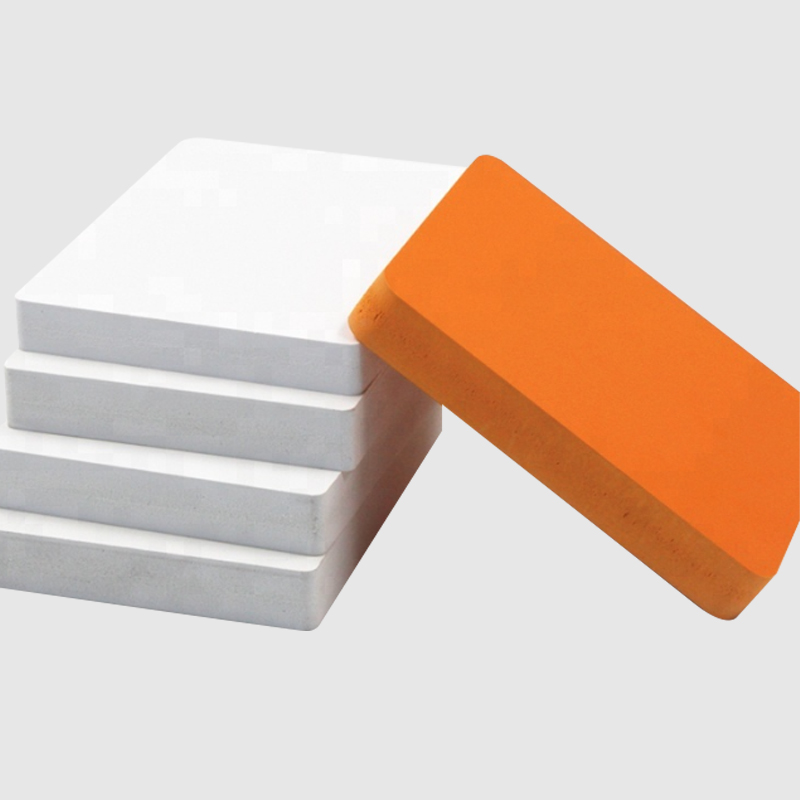

What is the difference between Celuka and Forex types?

Celuka refers to the manufacturing process creating a hard skin and firm core. Forex is a brand name often associated with similar PVC foam boards. Both types are applicable for WPC wall panel alternatives and furniture substrates.

English

English Español

Español عربى

عربى